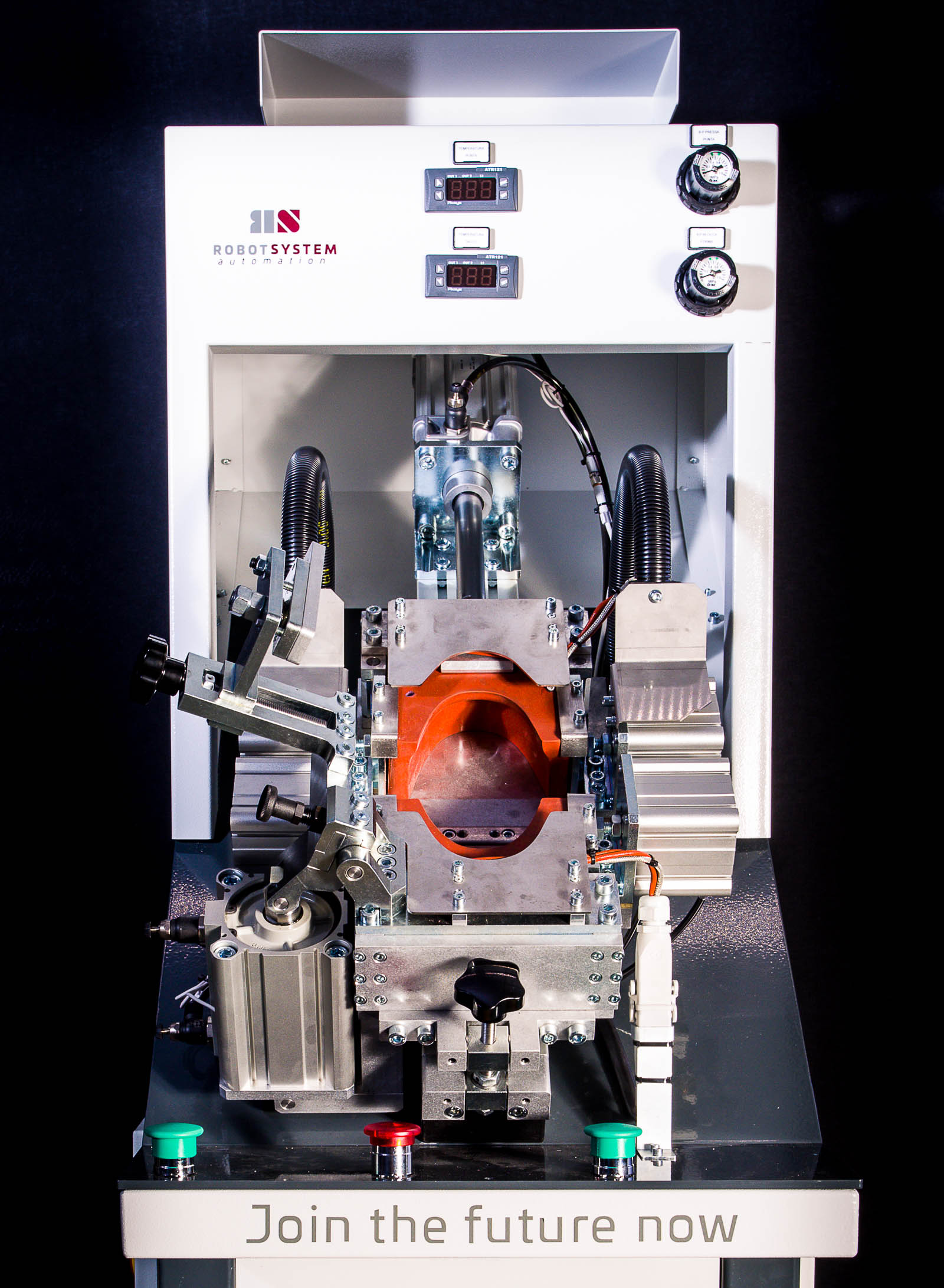

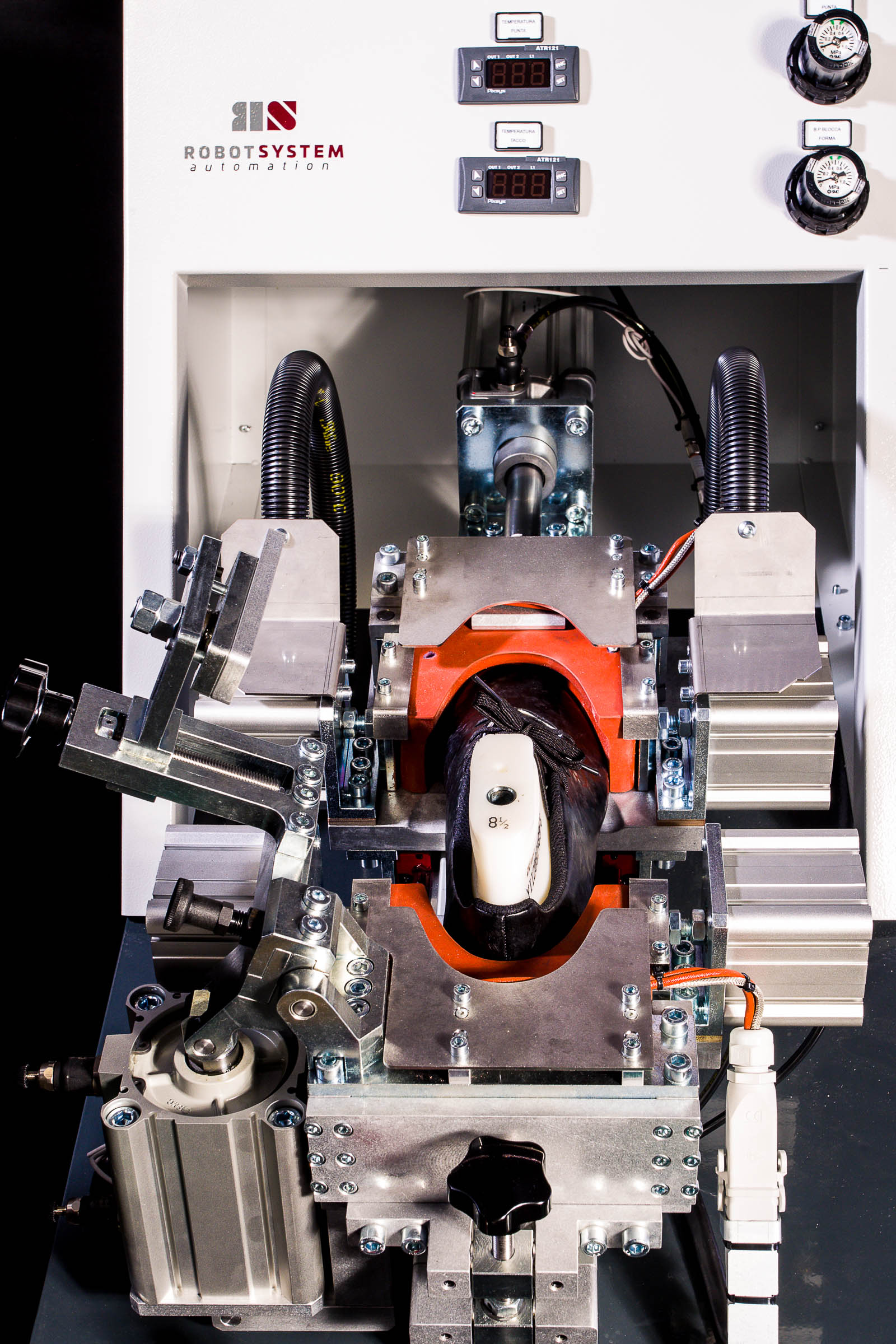

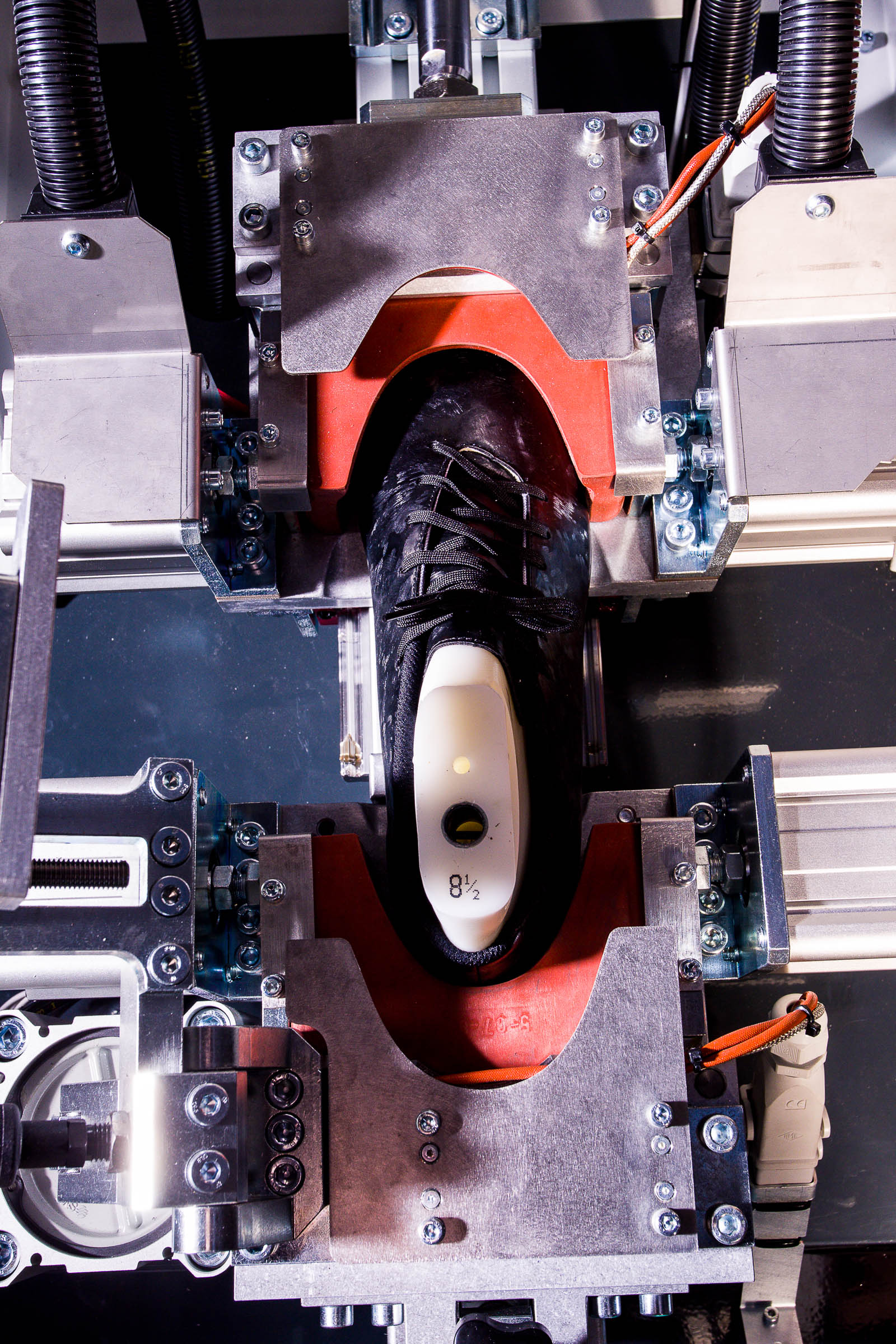

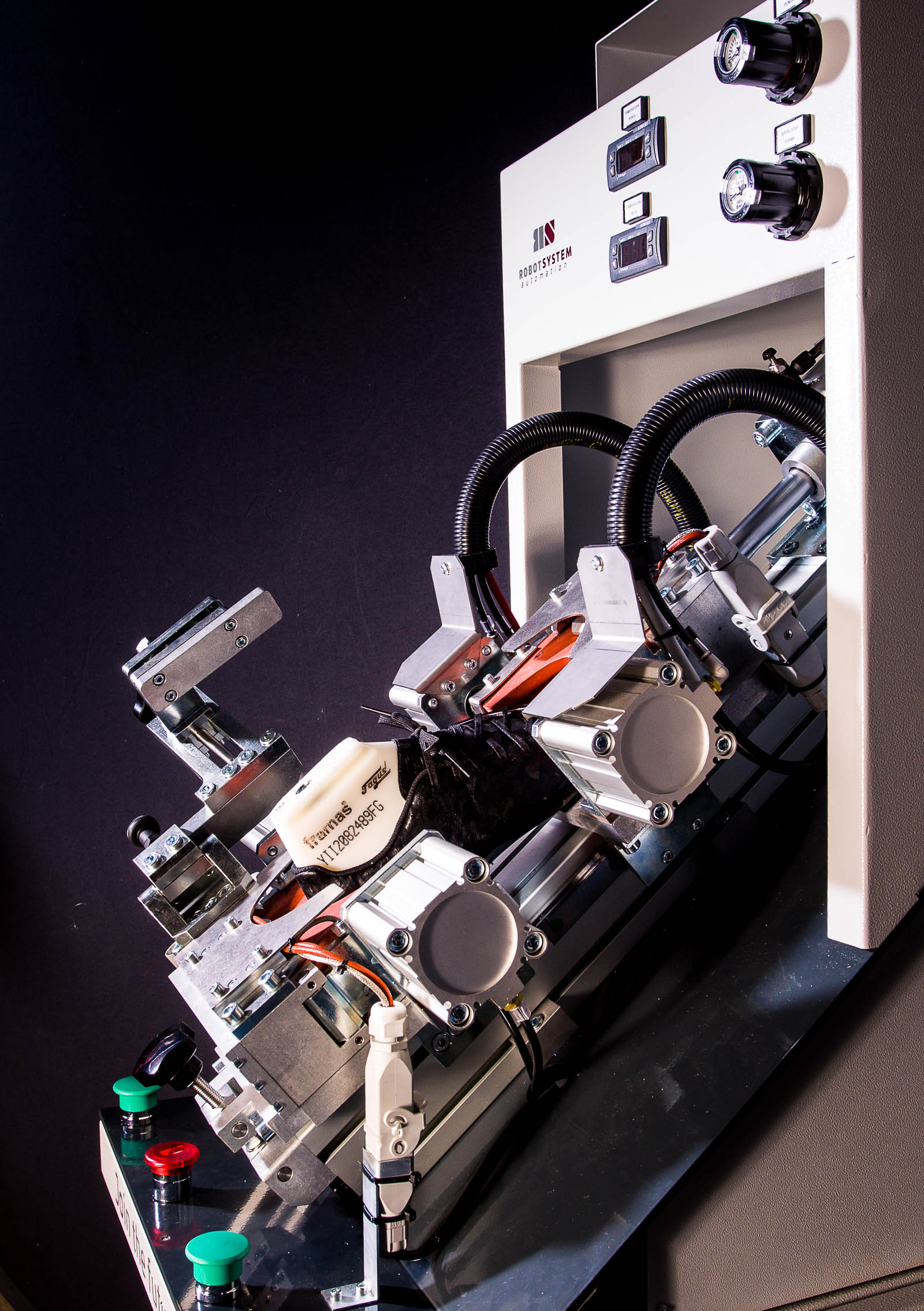

The Moulding Press for uppers, is a semi-automatic machine for uppers conformation, with silicone rubber pressers and adjustable heating systems.

Any remaining creases on the skin are completely eliminated.

It is the ideal solution for the shape and ironing of the folds on the side, heel and toe especially in shoes produced with a “Strobel” system.

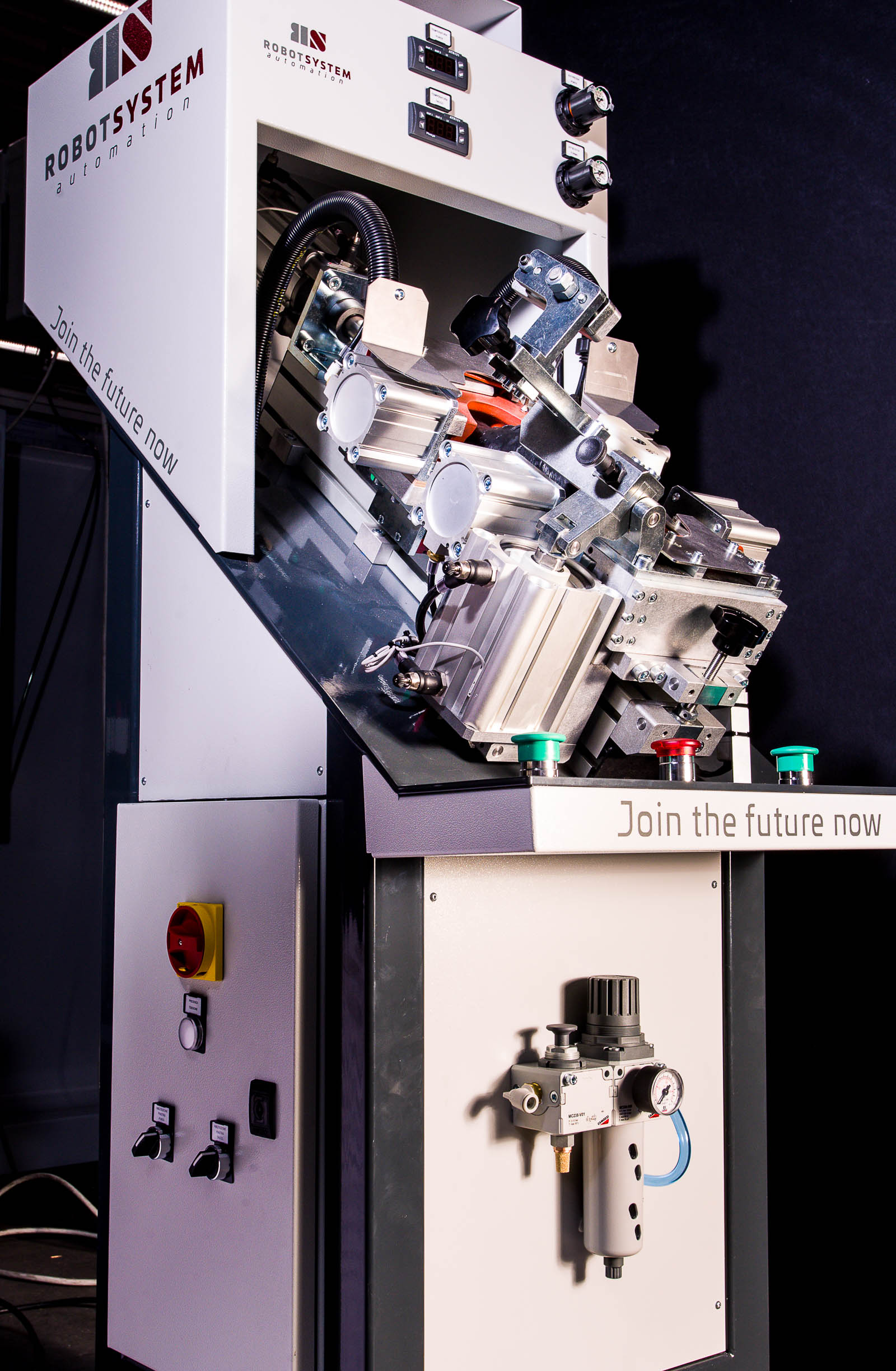

It is a simple, efficient machine which guarantees the highest quality of the final product. Thanks to its well-designed ergonomics for the tying operation, it makes the shaping step easy.

Composition:

- Welded and painted steel structure

- Recirculating ball handling slides

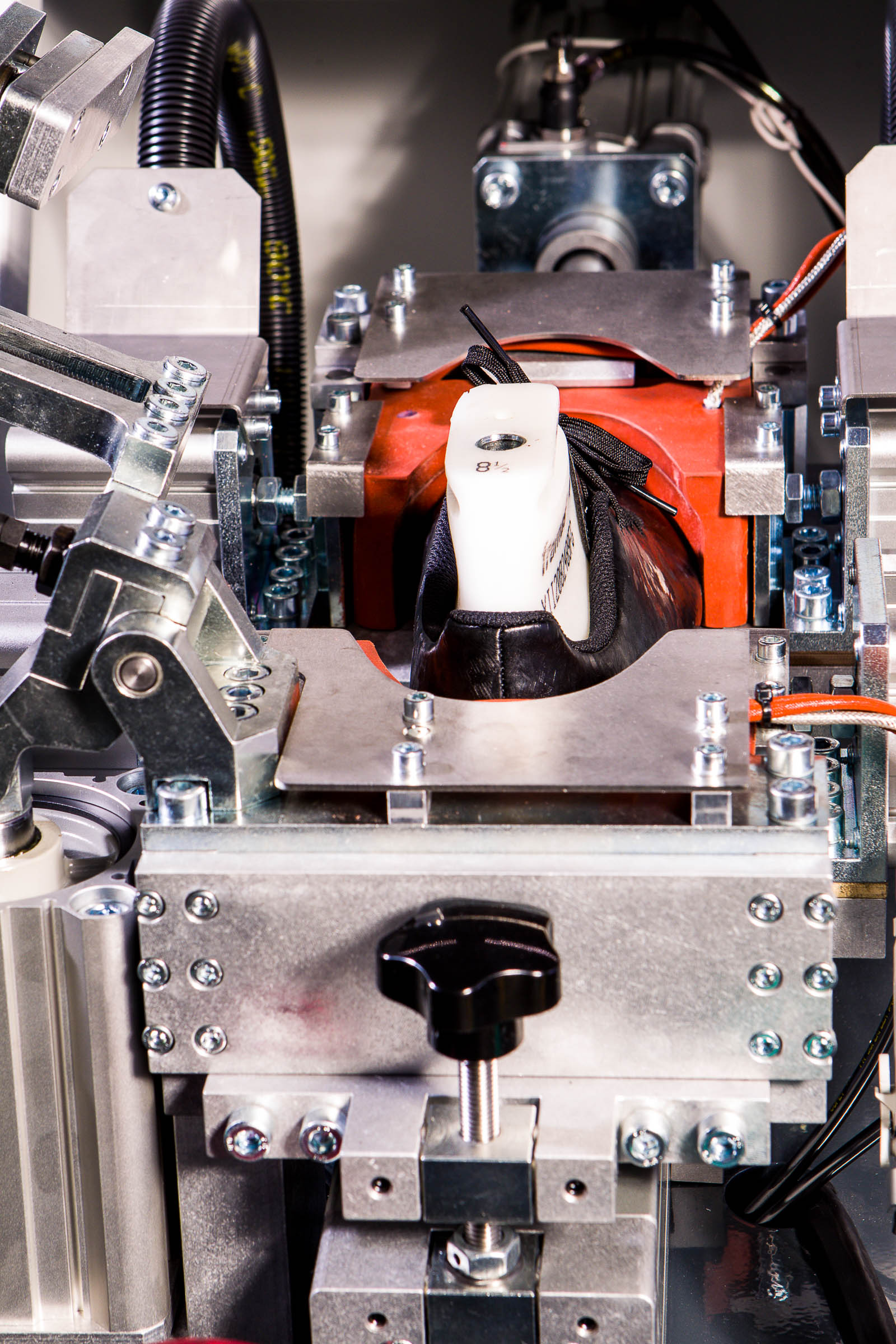

- Hot Top cushion conforming tip

- Heating stage for conformation

- Lower heat cushion heel conformation

- Lateral plungers for heel conformation

- Temperature control system cushions and programmable hot plate

- Complete control panel with PLC

- Pneumatic system

- Constructed with operator safety in mind

- Manuals for use and maintenance

Optional:

- Additional pneumatic pre-heating system